Author: Ing. Antonio Zavarce, March 23, 2023.

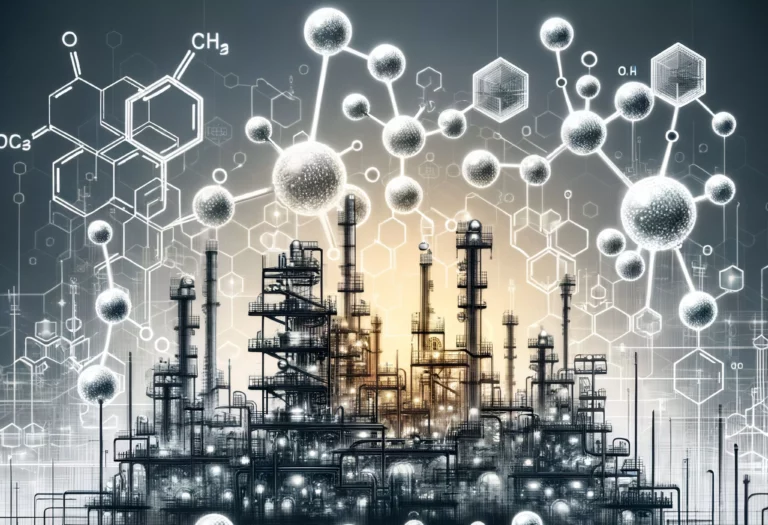

The pipeline protection industry is critical to ensuring the safety and efficiency of pipeline systems around the world. In this sense, there are various companies that offer a wide range of services and products to meet the needs and demands of the industry in the preservation of its assets. In this article, a description of the most important services and products offered for protection and inspection for this purpose will be presented .

Cathodic Protection and Pipeline Inspection Services

Corrosion in piping systems is a common problem in industries, which can lead to costly repairs and loss of productivity. Preventing corrosion is important to ensure the safety and efficiency of piping systems.

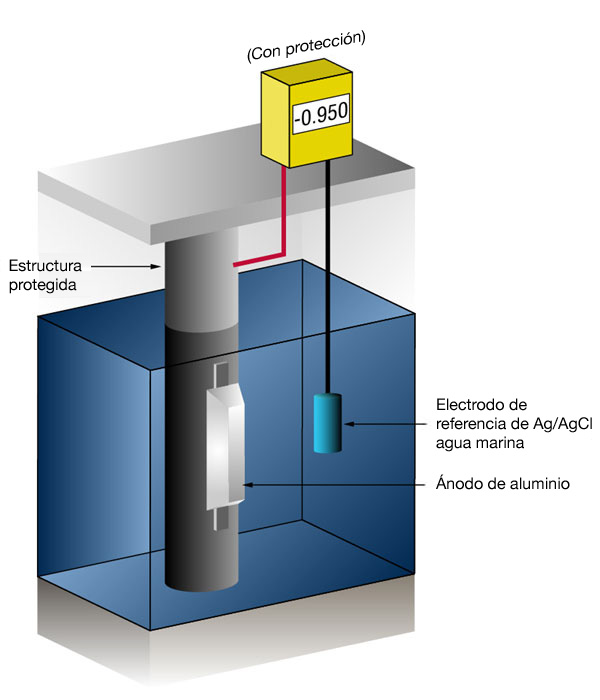

One of the most effective ways to prevent corrosion in pipeline systems is through Cathodic Protection (CP). It consists of a technique to control the corrosion of a metal surface (Structure to protect) turning it into the cathode of an electrochemical cell 1 . The simplest PC method is by connecting the metal to be protected with another more active metal acting as an anode in an electrochemical cell.

Cathodic protection systems are most commonly used to protect steel, water or fuel, pipeline transportation and storage tanks, ships, or an oil rig, both offshore 2 and on land.

One of the most important services of cathodic protection and pipeline inspection companies is corrosion monitoring and evaluation. Which represents a serious problem in piping systems, since it can weaken the structures and cause catastrophic failures. Corrosion monitoring services include measurement of pipeline surface corrosion, as well as assessment of pipeline integrity through leak detection and visual inspection. To carry out these services, specific measurement tools and test equipment are used, such as wall thickness gauges, leak detectors and remote monitoring systems.

Let’s talk about cathodic protection and inspection

Cathodic protection is an electrochemical process used to protect metals from corrosion in aggressive environments. It is achieved by applying an electric current to the pipe, which creates a protective electric field that prevents ions from the environment from attacking the pipe surface. For the installation of this system, specific products are required, such as sacrificial anodes and impressed current systems.

Visual inspection is also an important service in this industry, it is used to detect pipeline flaws such as cracks, deformations, and corrosion. This technique uses cameras and specific lighting tools, which are inserted into the pipe to examine the internal surface and is performed by operators or by remote controlled robots.

Equipment repair and calibration services are essential to guarantee the accuracy and correct operation of the equipment used in cathodic protection and pipeline inspection, so they must be calibrated regularly to ensure the accuracy of the measurements and the effectiveness of cathodic protection. In addition, they may require repair and maintenance to keep them working optimally. Repair and calibration services are carried out in specialized workshops, where highly trained technicians carry out specific inspections and repairs.

Cathodic Protection and Pipeline Inspection Products

Regarding products, there is a wide variety of specific tools and equipment for cathodic protection and pipe inspection. Some of the more common products include wall thickness gauges, leak detectors, remote monitoring systems, sacrificial anodes, impressed current systems, cameras, and visual inspection tools.

Wall thickness gauges are measuring tools used to determine the wall thickness of the pipe. These gauges can be manual or automated and are used to measure wall thickness, important information for monitoring and evaluating pipeline corrosion.

Leak detectors are tools used to identify the presence of leaks in the pipeline. They are used to locate leaks through the detection of sound, pressure or temperature changes. Early location of leaks is essential to prevent catastrophic failure in the piping system.

Visual inspection cameras and tools are used for the inspection of the internal surface of the pipeline. They are introduced into the pipeline for visual inspection. Illumination tools are also important in this type of evaluation, as they allow the internal surface of the pipe to be examined in detail.

Remote monitoring systems are tools that allow continuous monitoring of pipeline integrity from a remote control center. These systems can provide real-time information on corrosion, leaks, and other pipeline issues, allowing for rapid response to any problems that arise.

Sacrificial anodes are fundamental components in cathodic protection. These anodes are pieces of metal that are placed close to the metal structure and must be carefully selected based on the cathodic protection method to be applied, the material to be protected, and the exposure environment.

Impressed current systems use a direct current electrode to create an electrical field that protects the pipe from corrosion, they are particularly effective in highly corrosive environments, such as saline soils or marine environments.

Conclusion

In conclusion, the pipeline inspection and cathodic protection industry is critical to ensuring the safety and efficiency of pipeline systems around the world. The services and products offered in this industry are important in preventing corrosion, detecting failures, and maintaining pipeline integrity. Careful selection of the right services and products is essential to ensure effective pipeline protection and prevent catastrophic failure.

Discover how leaders in electronic solutions such as Tinker & Rasor are revolutionizing the industry with state-of-the-art cathodic protection instrumentation, effectively fighting corrosion. Assuring you of innovative design, reliability and proven performance, Tinker & Rasor offers the most advanced and practical instrumentation at competitive prices. Do not wait any longer to experience the peace of mind and efficiency that its solutions provide in the protection of your valuable assets. It’s time to join the vanguard and protect your investment!

References

- AW Peabody, Peabody Control of Ridge Corrosion, 2nd ed., 2001, NACE International. p.6, ISBN 1-57590-092-0

- https://www.llalco.com/proteccion-catodica/